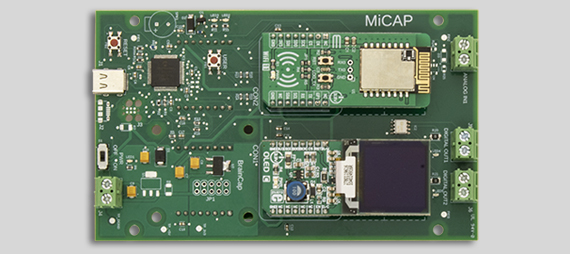

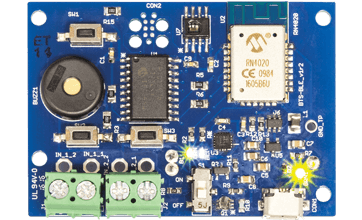

In today's marketplace customers expect and look for connectivity in the products they use. Now there is a cost effective way to get your products talking: connect them to the internet, send data to the cloud, connect them to smart phones and tablets. Now you can add sensing capabilities to monitor temperature, pressure, humidity, acceleration, motion, impacts, and more, and access that data remotely.

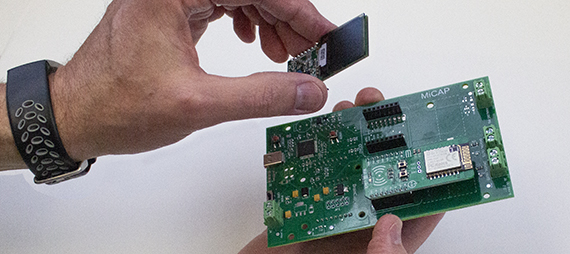

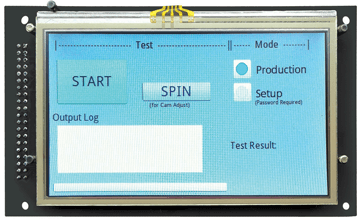

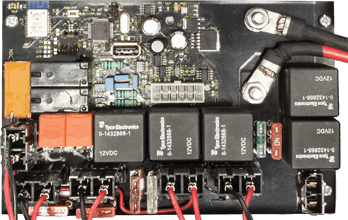

The BTS series is revolutionary; for the first time, manufacturers and end users have a low-cost option for adding WiFi/Bluetooth sensing capabilities to their new and existing products. API can add sensors directly to the board or add remote sensor capability. Or incorporate the components into your existing boards so there is no need to add any additional assemblies.